Mastering Precision: The Essential Guide to HM88 Manifold Systems in 2025

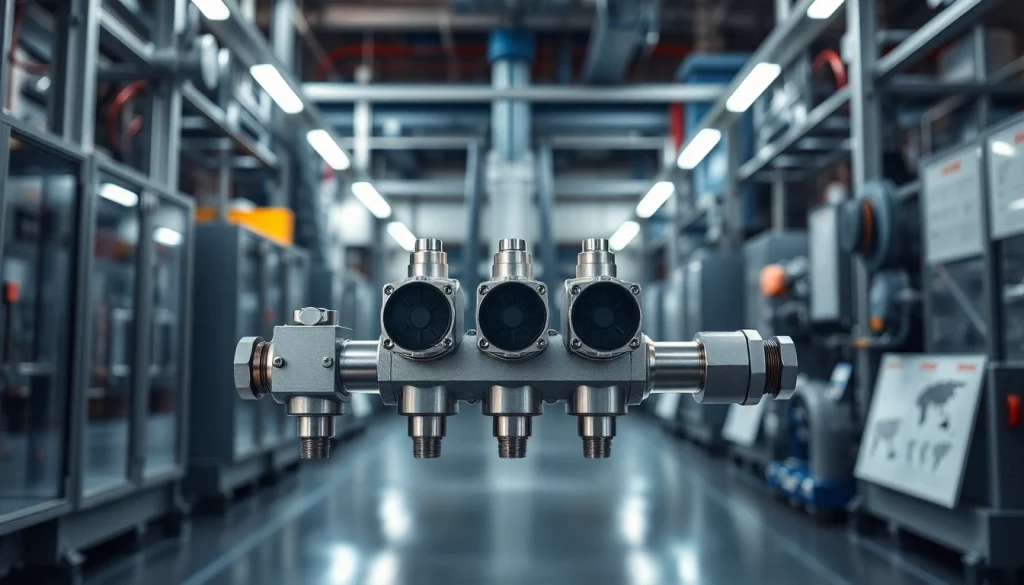

Understanding the HM88 Series Manifold

The HM88 Series Manifold is a sophisticated solution engineered for precision fluid control in various industrial applications. Designed for optimal performance, this series incorporates advanced features that facilitate seamless integration with differential pressure transmitters, making it an essential tool for engineers and technicians alike. When exploring options, hm88 offers comprehensive insights into manifold systems that cater to diverse operational needs.

What is the HM88 Series?

The HM88 Series represents a line of three-valve direct mount manifolds specifically designed for pressure measurement applications. These manifolds serve to connect pressure transmitters with process lines, providing a reliable means of isolating and venting the pressure sensor. The HM88’s robust construction ensures durability, making it ideal for environments that demand high performance.

Key Features of the HM88 Manifold

- Three-Valve Configuration: The series features a three-valve design allowing for precise venting and isolation of the sensing element.

- Compact Design: The direct mount capability minimizes space requirements, enhancing installation flexibility.

- High-Quality Materials: Constructed from premium materials to withstand various environmental conditions.

- Easy Integration: Compatible with many differential pressure transmitters, facilitating ease of use across different systems.

Applications in Various Industries

The versatility of the HM88 series manifolds allows its application across multiple industries, including but not limited to:

- Oil and Gas: Used for monitoring and controlling wellhead pressures.

- Chemical Processing: Essential in managing pressure in chemical reactors and storage vessels.

- Water Treatment: Implements pressure monitoring in water distribution systems.

- Pharmaceuticals: Assists in maintaining precise fluid dynamics critical for drug manufacturing.

Installation and Setup Guidelines

Proper installation of the HM88 series is crucial to ensure optimal performance and reliability. This section provides detailed guidelines to facilitate a seamless setup process.

Preparing for Installation

Before installation, gather all necessary tools and components, and review the installation manual for specific requirements. Ensure that the mounting surface is clean and free of debris to avoid misalignment of the manifold.

Step-by-Step Installation Process

- Begin by securing the manifold to the designated mounting bracket using appropriate fasteners.

- Connect the process lines to the manifold, ensuring that each connection is tight to prevent leaks.

- Install pressure transmitters onto the manifold, referring to the manufacturer’s specifications for torque requirements.

- Calibrate the system as per operational needs, utilizing pressure calibrators if necessary.

- Perform a leak test on all connections to confirm that the installation is secure and functioning as intended.

Common Installation Challenges and Solutions

During installation, some common challenges may arise, such as:

- Leakages: Ensure all connections are properly tightened; consider using PTFE tape for sealing.

- Alignment Issues: Check that the manifold is level and properly aligned with the process lines.

- Improper Calibration: Use certified calibration tools and follow manufacturer guidelines closely.

Maintenance Best Practices for HM88 Systems

To ensure long-term efficiency and reliability of the HM88 series manifold, regular maintenance is essential. The following best practices should be implemented as part of routine checks.

Routine Maintenance Procedures

- Visual Inspections: Conduct regular visual checks for wear and tear, leaks, and corrosion.

- Functional Testing: Regularly test the pressure transmitters and valves to ensure they operate correctly.

- Component Replacement: Replace any worn or damaged parts promptly to avoid system failures.

Identifying and Addressing Common Issues

Common issues that may arise with HM88 systems include:

- Pressure Fluctuations: Check for blockages in the lines and ensure that all valves are functioning properly.

- Inaccurate Readings: This may indicate a need for recalibration or replacement of the transmitter.

Long-term Care for Enhanced Longevity

Implementing a preventive maintenance schedule can significantly extend the lifespan of your HM88 system. Incorporate the following:

- Conduct a comprehensive system audit annually to assess all components.

- Keep detailed records of maintenance activities to track performance over time.

- Educate staff on proper usage and troubleshooting techniques to empower them in maintaining the system.

Performance Metrics and Efficiency Indicators

Monitoring performance metrics is vital in evaluating the efficiency of HM88 systems. This section outlines key performance indicators (KPIs) and methods for assessment.

How to Measure Efficiency in HM88 Systems

Efficiency can be measured by analyzing parameters such as response time, accuracy of readings, and operational pressure stability. Establish a baseline for normal operating conditions to facilitate effective comparison over time.

Key Performance Indicators to Monitor

- Response Time: Measure the time taken for the system to respond to pressure changes.

- Calibration Drift: Monitor the frequency of necessary recalibrations as an indicator of system performance.

- Operational Downtime: Keep a log of any downtime experienced and its reasons to identify improvement areas.

Case Studies on Performance Improvements

Several industries have reported significant performance improvements after implementing the HM88 series manifold:

- Oil Industry: Enhanced well monitoring efficiency led to a 15% increase in production.

- Pharmaceutical Sector: Improved fluid control in manufacturing reduced waste by 20%.

Future Trends in Manifold Technology

The future of manifold technology is poised for exciting innovations that will enhance functionality and performance. This section explores potential advancements and industry shifts expected by 2025.

Innovations Impacting the HM88 Series

Future iterations of the HM88 series may incorporate smart technology, including:

- IoT Integration: Enabling remote monitoring and data analysis to enhance operational efficiency.

- Self-Diagnostics: Systems that can alert operators to maintenance needs before issues arise.

Anticipated Industry Shifts in 2025

By 2025, industry shifts are likely to include:

- Increased Automation: More processes will rely on automated systems for fluid control.

- Sustainability Practices: A greater focus on environmentally friendly materials and processes in manifold design.

Preparing for Future Developments in Fluid Control

To stay ahead, industries must invest in training and development, ensuring personnel are well-equipped to adapt to new technologies. Regularly updating equipment and practices in line with emerging trends will also keep systems efficient and competitive.